Company History

S & J Manufacturing, where cutting-edge technology meets five decades of unmatched expertise in the oil and gas industry. Specializing in Artificial Lift Systems, CNC Custom Fittings, and comprehensive manufacturing setups, we offer tailored solutions for every project—whether it requires advanced automation or detailed craftsmanship. For large jobs with tight deadlines, our automated processes ensure timely, high-quality results.

Founded 50 years ago, S & J Manufacturing is a family-owned and operated business that has grown from a small workshop to a leading force in the oil and gas manufacturing industry. Our journey has been marked by a dedication to quality, precision, and the satisfaction of our clients, including industry giants like Ditch Witch and Schlumberger

Advanced Automation Technology

To stay at the forefront of technology and innovation, S & J Manufacturing is committed to continuous improvement and investment in new technologies. We regularly review and update our systems to incorporate the latest advancements, enhancing both our automation capabilities and custom craftsmanship processes. This ongoing commitment ensures that we can adapt to evolving industry standards and client needs, delivering exceptional results for every project.

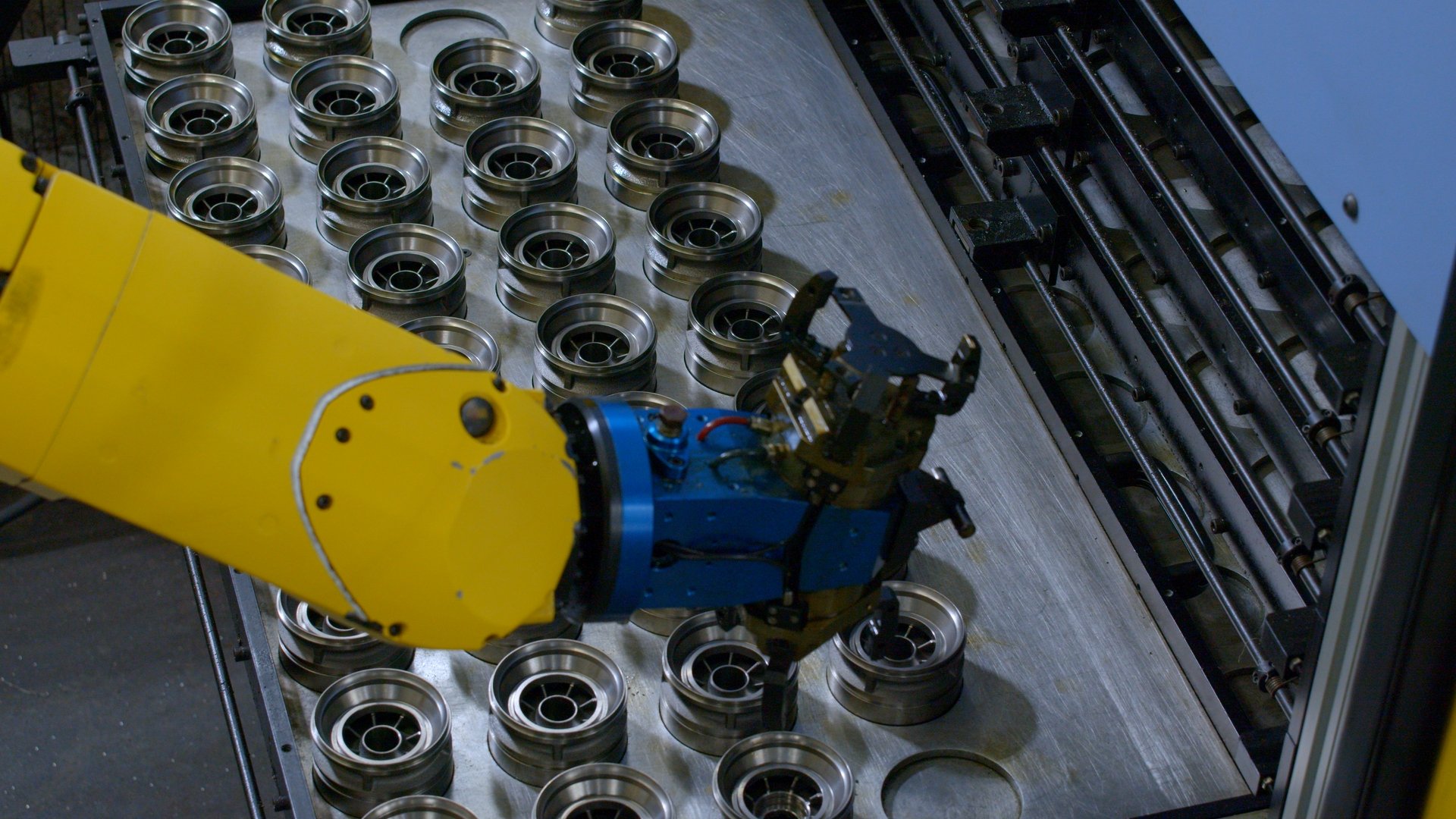

Robotic Assembly Lines: Our facility is equipped with robotic arms and automated conveyors that handle repetitive tasks with speed and precision. This setup reduces human error and increases production efficiency, allowing us to meet tight deadlines without compromising quality.

Smart Sensors and IoT Integration: By incorporating smart sensors and IoT technology, we continuously monitor and analyze machinery performance and production parameters. This real-time data allows us to proactively address potential issues, optimize machine settings, and reduce downtime, ensuring consistent quality and timely delivery.

Automated Quality Control Systems: We utilize high-resolution cameras and machine learning algorithms to perform automated inspections and quality checks. These systems detect defects or deviations from specifications with exceptional accuracy, ensuring that every product meets our rigorous quality standards.

Advanced Scheduling Software: Our production scheduling software uses AI and predictive analytics to optimize workflows, balance workloads, and minimize bottlenecks. This technology allows us to efficiently manage complex project requirements and adapt quickly to changing priorities.