Trusted By

Advanced Automation

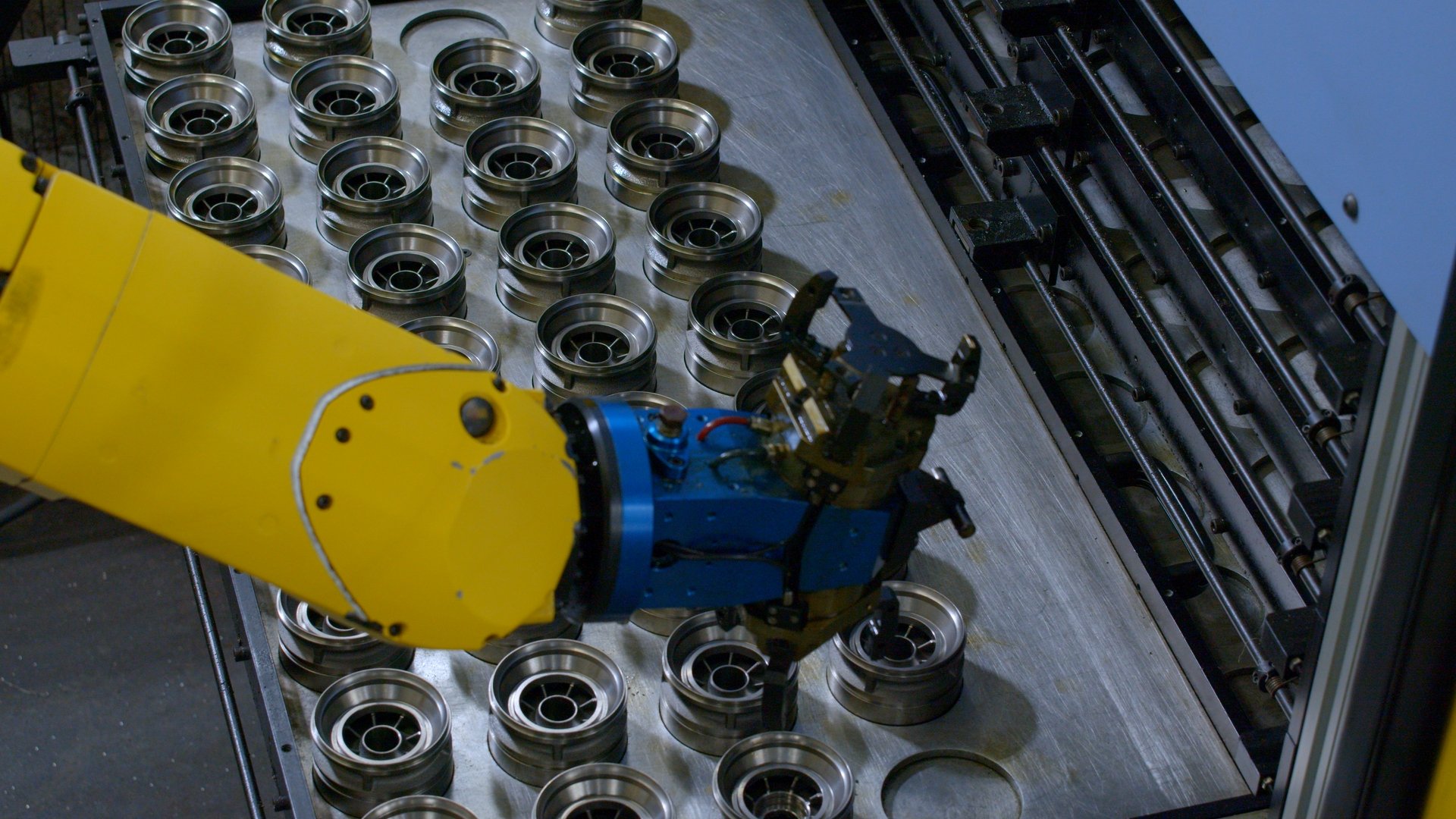

Streamlined Precision at Scale

At S & J Manufacturing, our facility is equipped with cutting-edge robotic systems and automated processes that ensure unparalleled efficiency and accuracy. We utilize automated assembly lines, robotic arms, and intelligent systems that can handle intricate tasks with consistency. For example, our automated CNC milling process integrates real-time monitoring and adjustments, reducing the chance of error to near-zero levels. This allows us to not only meet tight deadlines for large-volume orders but also to maintain superior quality across every unit produced. The reduction in manual intervention also minimizes production costs, providing a more cost-effective solution for our clients.

How does this impact you?

By employing advanced automation, we can accelerate project timelines and deliver large quantities of components with consistent quality, helping our clients stay ahead in competitive markets. Our automation also allows for flexible scalability, adapting quickly to changes in order volume without compromising on delivery schedules.

CNC & Manual Milling

Versatile Machining for Every Need

S & J Manufacturing combines the precision of CNC machining with the adaptability of manual milling to offer comprehensive solutions for any project. Our state-of-the-art CNC machines utilize CAD/CAM software to produce highly intricate parts with tight tolerances, ideal for high-volume production. These machines are capable of multi-axis operations, enabling the creation of complex geometries in a single setup, which reduces production time and costs. Meanwhile, our manual milling services are perfect for prototypes, one-offs, or jobs requiring a high degree of customization. Skilled machinists oversee these projects, applying decades of experience to ensure each part meets exact specifications.

How Does This Help?

This dual approach allows us to offer flexible solutions that cater to both large-scale production needs and specialized custom orders. Clients benefit from reduced lead times, lower costs, and the ability to receive components tailored to their exact requirements, whether for critical operational parts or innovative new designs.

Custom Modifications

Our modification services include precision resizing, re-machining of surfaces, and altering geometries to improve the fit and function of parts within specific applications. Leveraging our advanced CNC technology, we can perform complex modifications with high precision, ensuring that each part adheres to stringent industry standards. We also offer material enhancements, such as heat treatments and surface finishing, to extend the durability and operational lifespan of modified components.